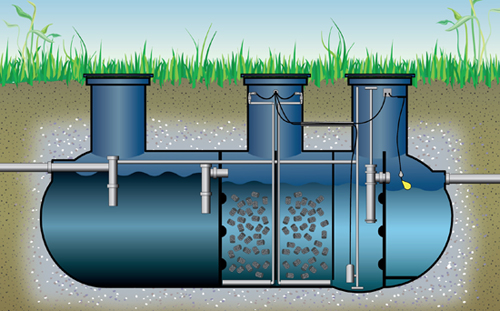

Bioreactors

Purpose/Function:

This new conservation practice to the region mimics natural processes to reduce nitrogen coming off farm fields’ drainage systems. In certain applications, slag can be placed at the outfall of the reactor to assist in the reduction of phosphorous.

Initiation protocol:

Site selection requires a predictable flow of subsurface groundwater from natural drainage patterns or previously constructed subsurface tile drainage systems.

Public acceptance:

Growing, as this is a new practice for the Eastern U.S. The agricultural community finds this edge-of-field practice a benefit becasue little to no land is taken out of production in most cases.

Implementation Factors (level of difficulty):

Easy to Moderate.

Funding Sources / Options:

Grant funding may be available through the Chesapeake Bay Trust, the Maryland Department of the Environment, National Fish Wildlife Foundation and/or private foundations. It is anticipated that this practice will soon become eligible for state cost-share funding through Maryland Department of Agriculture programs.

Costs:

Installation cost of approximately $10,000 to treat 30 to 80 acres of contributing drainage.

Load Reduction Efficiency:

Where they are more common in the Midwestern U.S., bioreactors have provided annual nitrate load reductions between 23 and 98 percent (averaging approximately 45 percent) within agricultural tile drainage systems. Bioreactors are generally accepted as providing roughly 25 to 50 percent nitrogen loss reduction in the Midwest.

Average Total Nitrogen removed per acre of practice per year = TBD

Cost per pound removed = TBD, but initial research suggests this cost-effective practice will yield approximately $7.00 per pound of nitrogen removed at edge of field.

Average Total Phosphorous removed per acre of practice per year = N/A

Average Total Suspended Solids removed per acre of practice per year = N/A

Operation & Maintenance:

Only a few hours per year are required for maintenance over a lifetime of roughly 10 years.

Helpful Links:

- https://www.bing.com/videos/search?q=woodchip+bioreactor+youtube&qpvt=woodchip+bioreactor+youtube&view=detail&mid=AC56E8F14C8672B50DF2AC56E8F14C8672B50DF2&FORM=VRDGAR

- http://www.mda.state.mn.us/protecting/cleanwaterfund/research/woodchipbioreactors.aspx

- https://www.youtube.com/watch?v=Oc8eDVOUMZw

- https://experts.illinois.edu/en/publications/performance-of-denitrifying-bioreactors-at-reducing-agricultural-

Local Project Examples:

Midshore Riverkeeper Conservancy (now called ShoreRivers) has installed two bioreactors on farms in the Choptank watershed. One farm is a conventional commodity crop application while the other is installed on a dairy farm.

MRC has secured funding for the design and construction of eight bioreactors. Their monitoring data and analysis shows potential reductions in nitrogen concentration of more than 90 percent. These results have generated widespread interest, and the practices will soon become eligible for state cost-share funding and likely TMDL credit.

Contact Information:

Tim Rosen

443-385-0511

Related Best Management Practices

Feedback on This Best Practice