Denitrification (Best Available Technology Systems)

Purpose/Function:

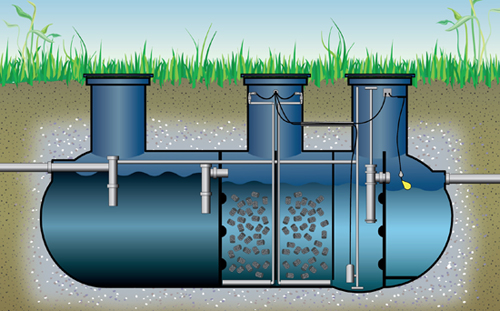

The installation of best available technology (BAT) to a septic system reduces nitrogen discharges by approximately 50 percent. BAT typically replaces or works in combination with the septic tank. The unit’s biological processes are used to promote the release of nitrogen as a harmless gas into the atmosphere. Advanced pretreatment units may include electrical and mechanical components such as pumps, blowers, floats, alarms, diffusers and electronic control panels.

Initiation protocol:

The Maryland Department of the Environment has an approved list of BAT systems that can be installed in the state (and in some locations, it is mandatory for new and replacement systems).

Public acceptance:

Mixed – although the benefits are easily conveyed, the high cost of these systems are a barrier to widespread acceptance.

Implementation Factors (level of difficulty):

Moderate. Can be installed by a licensed septic contractor.

Funding Sources / Options:

The Bay Restoration Fund provides grants to cover part or all the cost for nitrogen-reducing pretreatment units. The Linked Deposit Loan Program discounts the loan interest rate to install a nitrogen reducing system or to repair or replace a failed septic system. To determine eligibility and more information, visit MDE’s website: http://mde.maryland.gov/programs/Water/BayRestorationFund/Pages/index.aspx

Costs:

Costs estimated as $ per system installed.

Denitrification in Critical Area, 1,000 ft from Stream :

| Cost Estimates | EPA | Task Force | Average |

| Initial | $9,653 | $13,000 | $11,326.50 |

| Annual | $341 | $- | $170.50 |

| Lifespan (yrs) | 20 | 20 | 20 |

| Annualized | $823.65 | $650 | $736.83 |

Load Reduction Efficiency:

Denitrification – Critical Area

Total Nitrogen removed per system per year

|

Low 7.78 lbs. |

Medium 8.82 lbs. |

High 9.17 lbs. |

Cost per pound removed = between $80 and $95

Total Phosphorous removed per system per year = N/A

Total Suspended Solids removed per system per year = N/A

Denitrification – 1,000 feet from stream:

Total Nitrogen removed per system per year

|

Low 4.85 lbs. |

Medium 5.55 lbs. |

High 5.88 lbs. |

Cost per pound removed = between $125 and $152

Denitrification – Other:

|

Low 2.91 lbs. |

Medium 3.36 lbs. |

High 3.53 lbs. |

Cost per pound removed = between $209 and $253

Operation & Maintenance:

Advanced pretreatment units have electrical and mechanical components requiring periodic maintenance and inspections by a qualified contractor. The frequency of inspection and maintenance will vary based on the type of unit. Manufactured units should follow the manufacturer’s maintenance requirements. Engineer-designed units should follow inspection and maintenance requirements recommended by the designer.

Climate Change Considerations:

N/A

Planning Questions to Consider:

An operation and maintenance service contract is required for all properties with a nitrogen-reducing unit. The overall effectiveness of a nitrogen-reducing system and its level of wastewater treatment depend upon the use of the system. Bleach, detergents and household chemicals should be used sparingly. All leftover food and grease should be discarded as solid waste in garbage cans.

Technical Notes:

A list of approved service contractors is listed on the Maryland Department of the Environment website at www.mde.maryland.gov

Related Best Management Practices

Feedback on This Best Practice